The Benchmark

The Plaid motor came from late-night problem-solving and an obsession with making electrons move smarter, cooler, and quicker than any machine before it. A revolutionary benchmark.

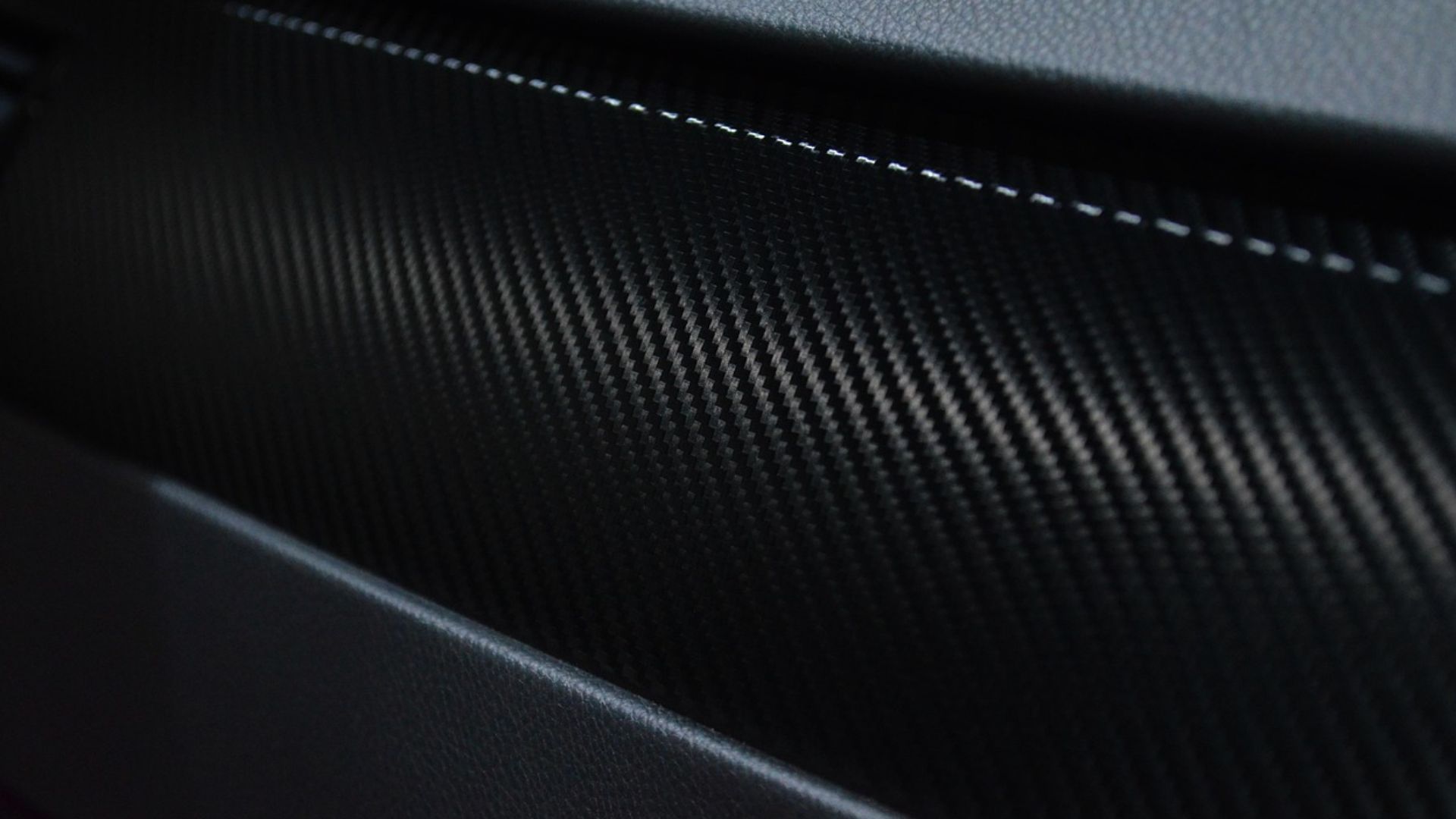

Carbon-Fiber Rotor Containment For Ultra-High RPMs

At the heart of the Plaid motor sits a carbon-fiber-wrapped rotor—a material choice more common in aerospace than autos. It holds the spinning copper core together under immense stress, letting Tesla’s motor reach record revolutions without tearing itself apart.

Christine Twigg, Wikimedia Commons

Christine Twigg, Wikimedia Commons

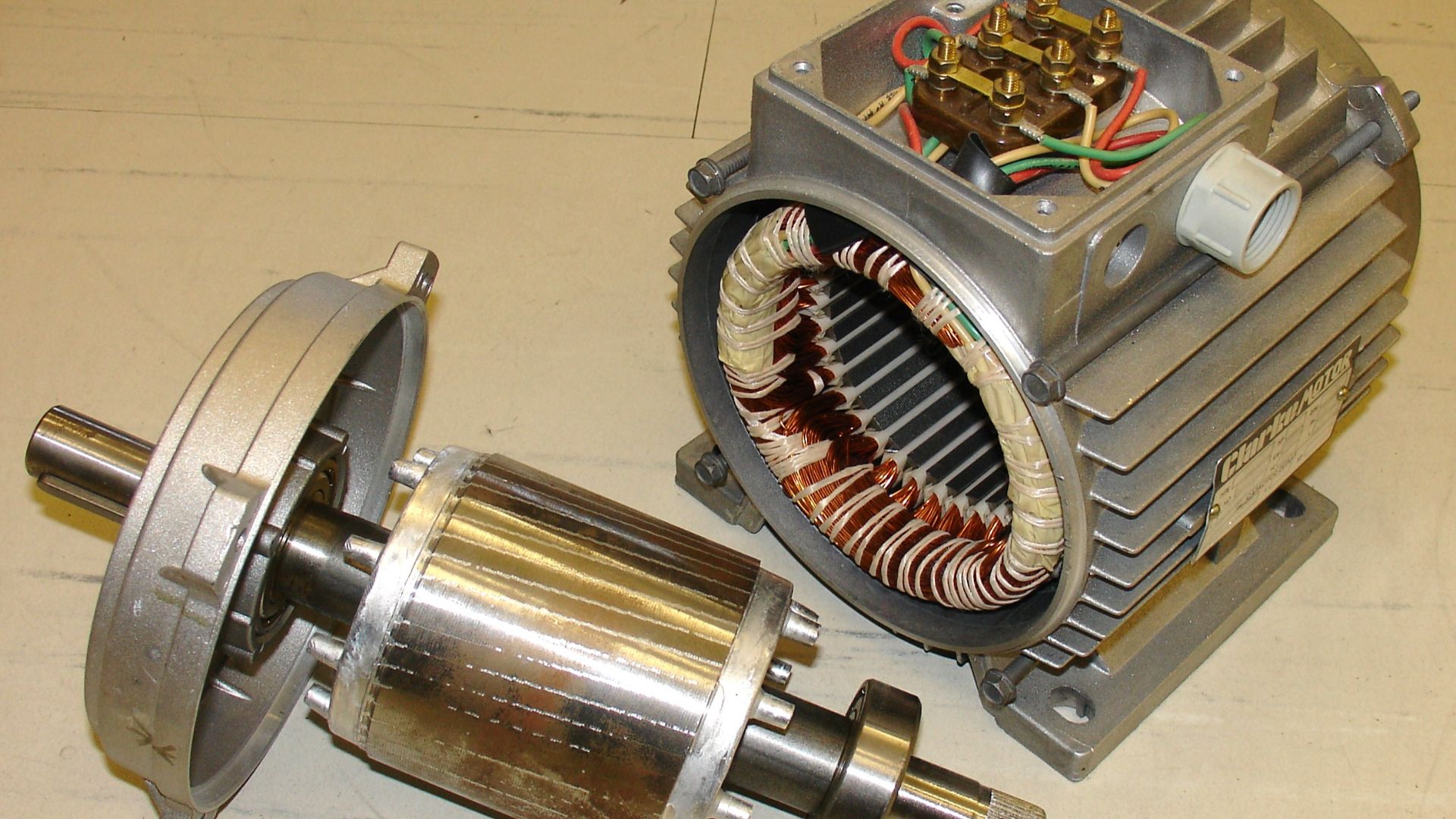

Tri-Motor Torque Vectoring For Precision Control

The Plaid’s three-motor setup changes everything about traction. One up front, two in the back, each controlled independently. That setup lets Tesla fine-tune torque instantly. This also gives every wheel its perfect share of power. Corners feel deliberate, sharp, and almost eerily balanced, even under extreme acceleration.

Alison Cassidy, Wikimedia Commons

Alison Cassidy, Wikimedia Commons

A Build Aimed To Outperform Gas Supercars

Tesla aimed squarely at the supercar crowd. The Plaid motor’s instant torque and zero-shift acceleration made traditional engines look slow to respond. By beating performance legends in real-world sprints, Tesla proved electric speed wasn’t theoretical anymore—it was something you could feel pinning you to the seat.

Alexander-93, Wikimedia Commons

Alexander-93, Wikimedia Commons

Redefine Global EV Performance Standards

Every automaker claims to push limits; Tesla redefined what “limit” meant. With their Plaid powertrain, they raised the benchmark for electric performance by blending raw energy with control. It reimagined how speed and stability could coexist in one seamless electric experience.

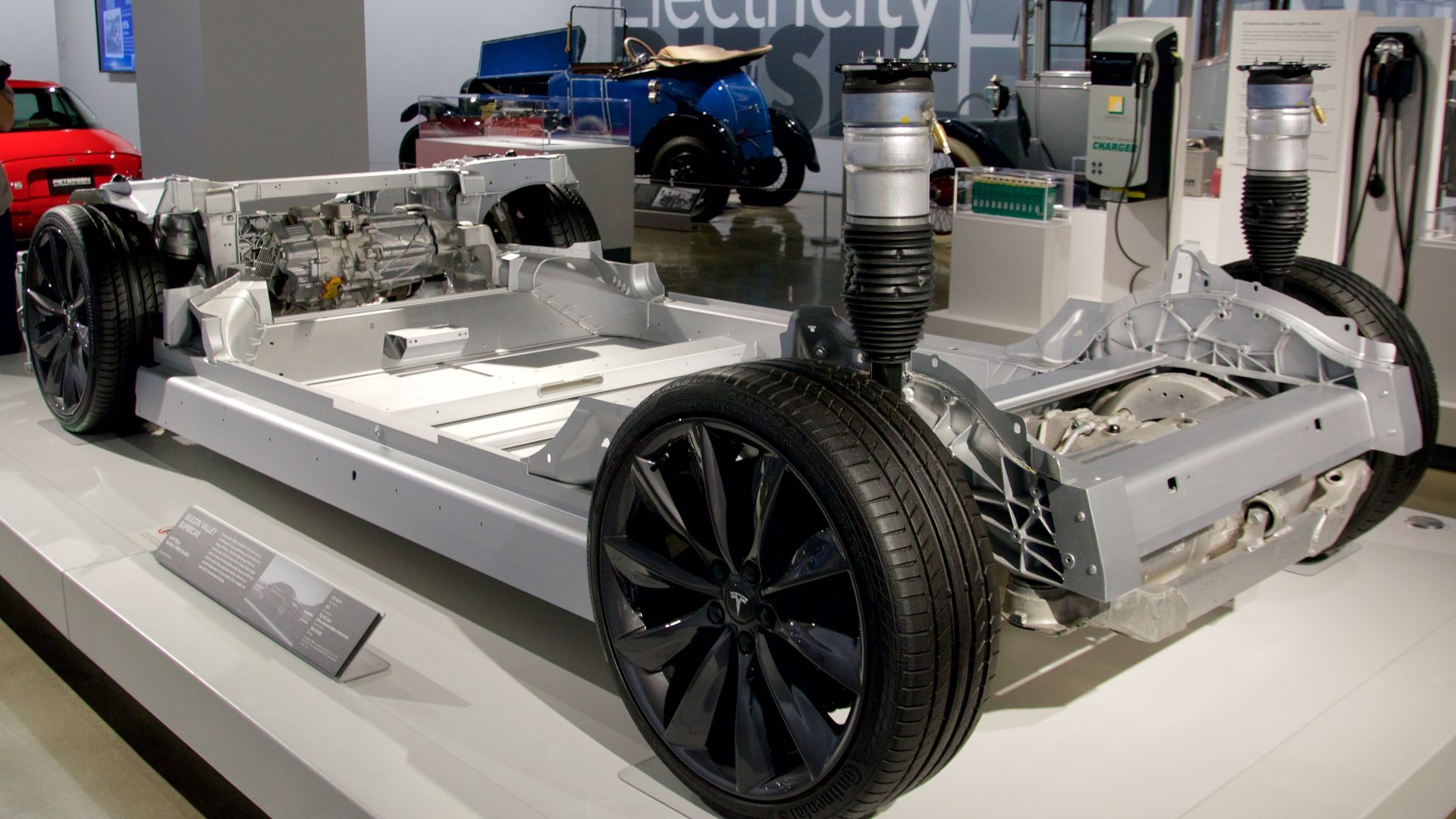

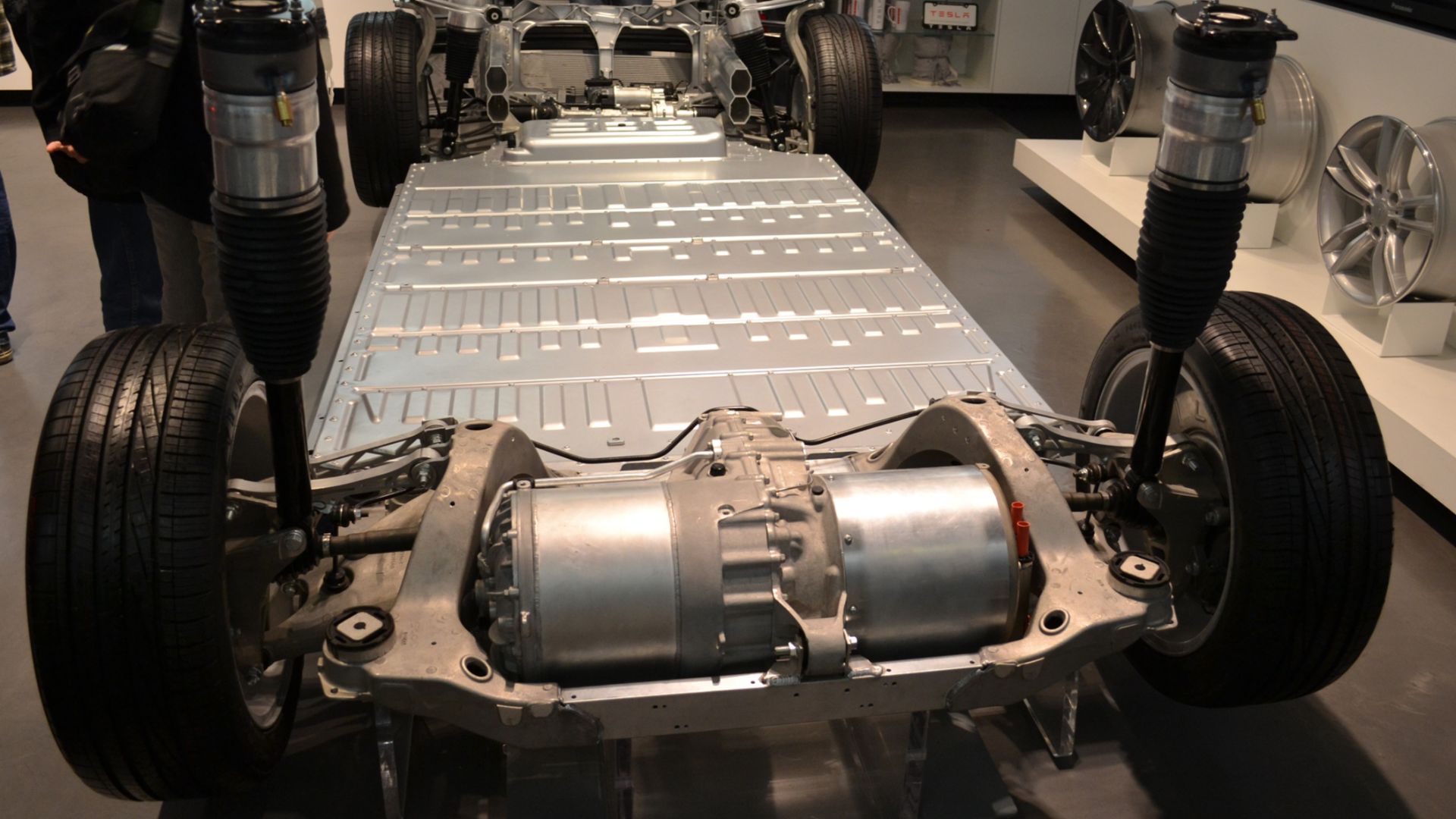

Remove Need For Complex Gearboxes

Instead of layering on gears, Tesla engineered the Plaid motor to handle wide speed ranges on its own. By eliminating mechanical shifting, the design cuts weight, friction, and parts that typically wear down. The result? Smooth, relentless acceleration and fewer headaches for both driver and machine.

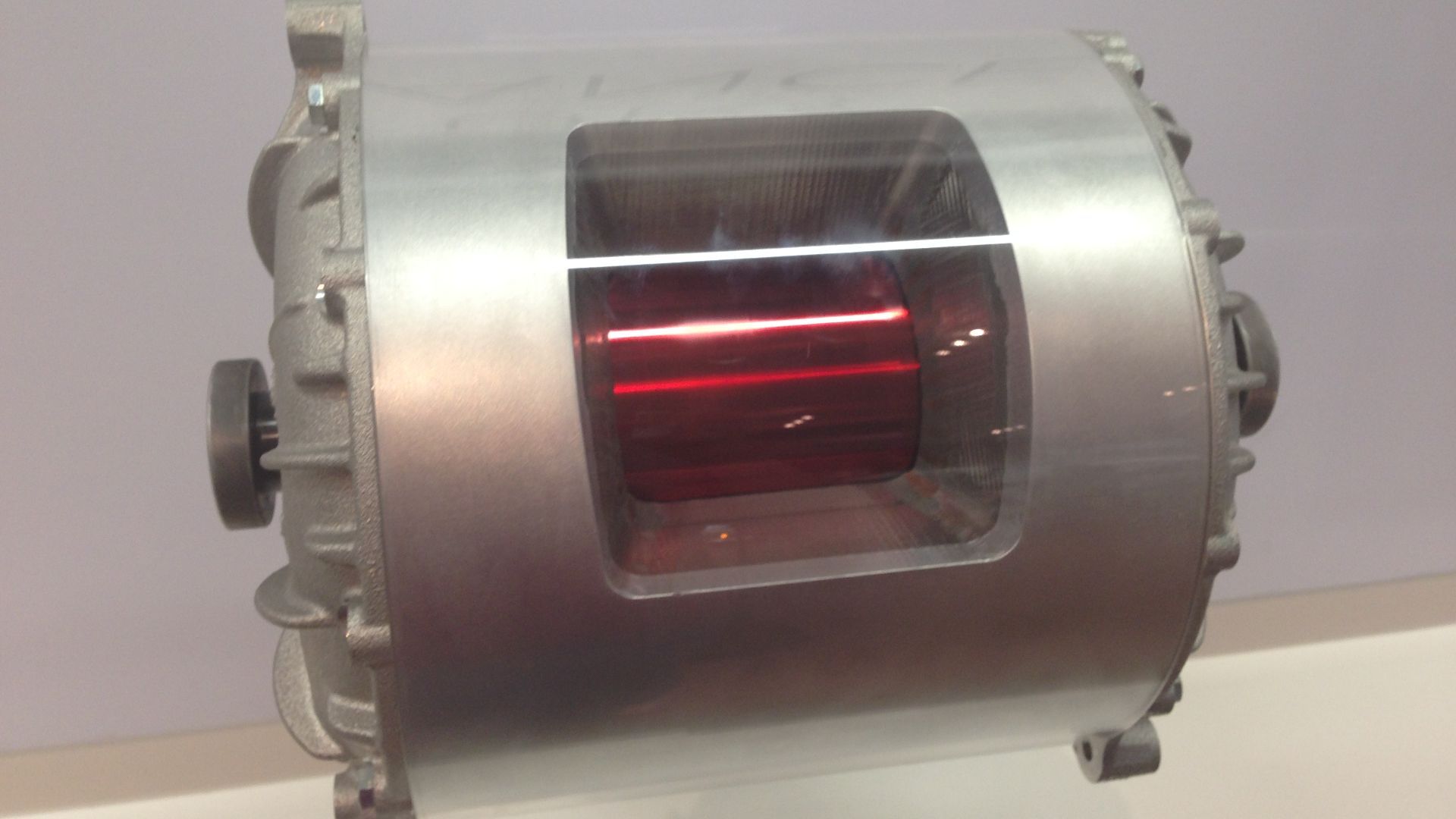

Achieve Superior Thermal Management For Sustained Power

Heat is every electric motor’s enemy, and Tesla tackled it head-on. The Plaid uses oil-cooled stators, advanced channels, and smart circulation to keep temperatures stable under punishing loads. That system lets it maintain maximum output for far longer than earlier Tesla models or rivals could dream.

Showcase Tesla’s In-House Engineering Mastery

Building the Plaid powertrain in-house was also about proving capability. Tesla’s engineers designed everything from the rotor to the cooling systems internally. Owning every layer meant faster innovation and tighter integration. The result was a level of power and efficiency no combustion engine could ever achieve.

Steve Jurvetson from Los Altos, USA, Wikimedia Commons

Steve Jurvetson from Los Altos, USA, Wikimedia Commons

Deliver Peak Performance Through Mechanical Simplicity

Tesla’s secret was to use fewer moving parts. Tesla’s Plaid motor’s simplicity hides layers of sophistication in software and materials. All components operate at their limits, yet with less friction and complexity than in older designs. It’s minimalism engineered for power, not just style.

Bill Abbott, Wikimedia Commons

Bill Abbott, Wikimedia Commons

History's most fascinating stories and darkest secrets, delivered to your inbox daily.

Boost Tesla’s Premium Brand Prestige

The Plaid name signals exclusivity. Tesla positioned it as a halo model, proof that electric luxury could rival the world’s best grand tourers. For buyers, owning one was, of course, about acceleration; but mostly, it was about driving the company’s vision of the future.

Use Advanced Materials For Rotor Stability

Carbon fiber was a necessity. The Plaid rotor experiences forces so extreme that steel alone would fail. By wrapping it in tensioned carbon fiber, Tesla achieved unmatched strength-to-weight balance, creating a motor capable of sustained, stable speed far beyond typical electric limits.

Oak Ridge National Laboratory, Wikimedia Commons

Oak Ridge National Laboratory, Wikimedia Commons

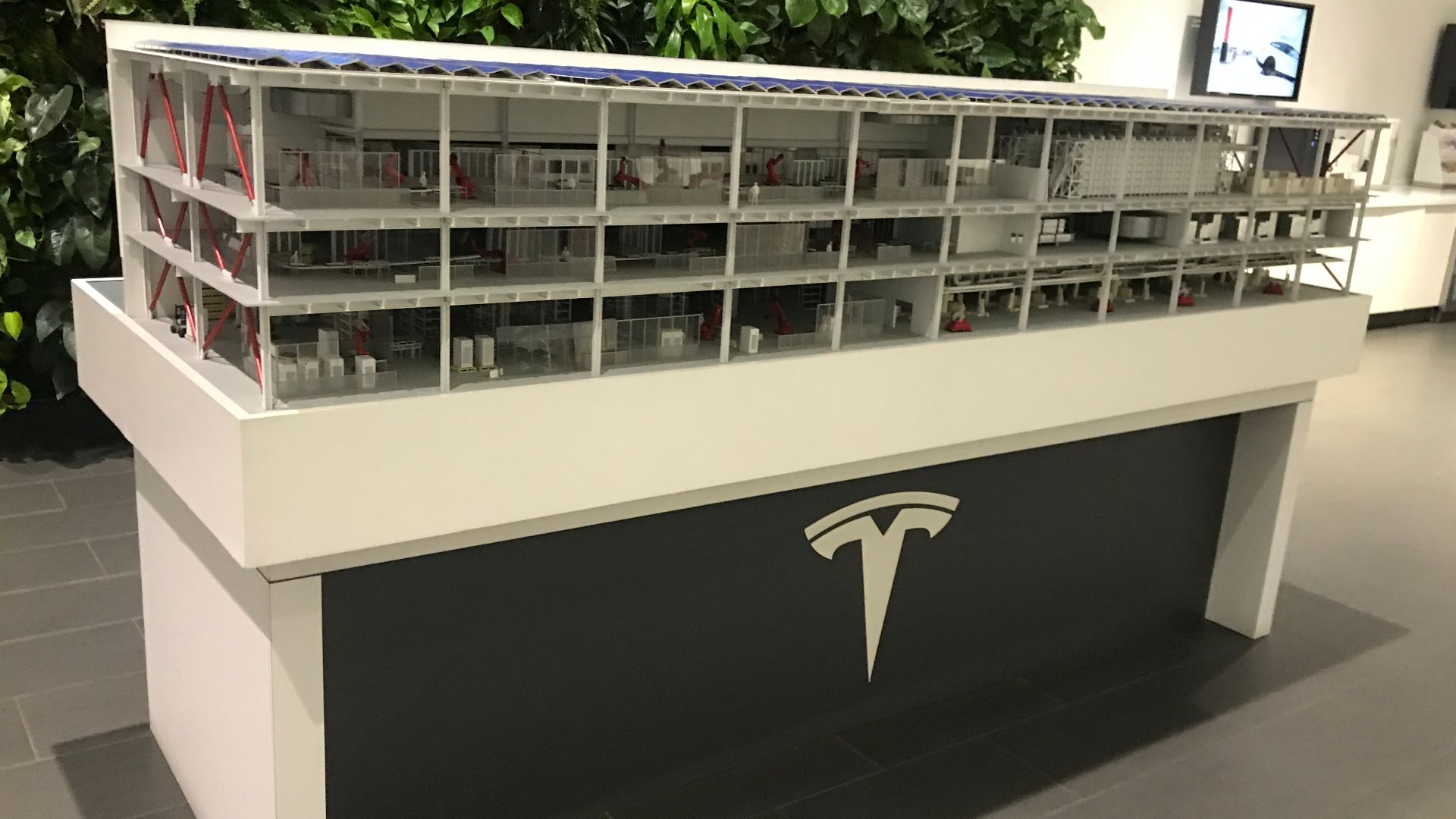

Ensure Scalability For Future Tesla Models

Every breakthrough inside the Plaid’s housing doubled as groundwork for future Teslas. Engineers designed components that could scale down into everyday vehicles. This meant that high-performance ideas could flow into mass-market cars without massive redesigns. That forward-thinking approach kept innovation affordable across Tesla’s growing lineup.

Kenneth Lund, Wikimedia Commons

Kenneth Lund, Wikimedia Commons

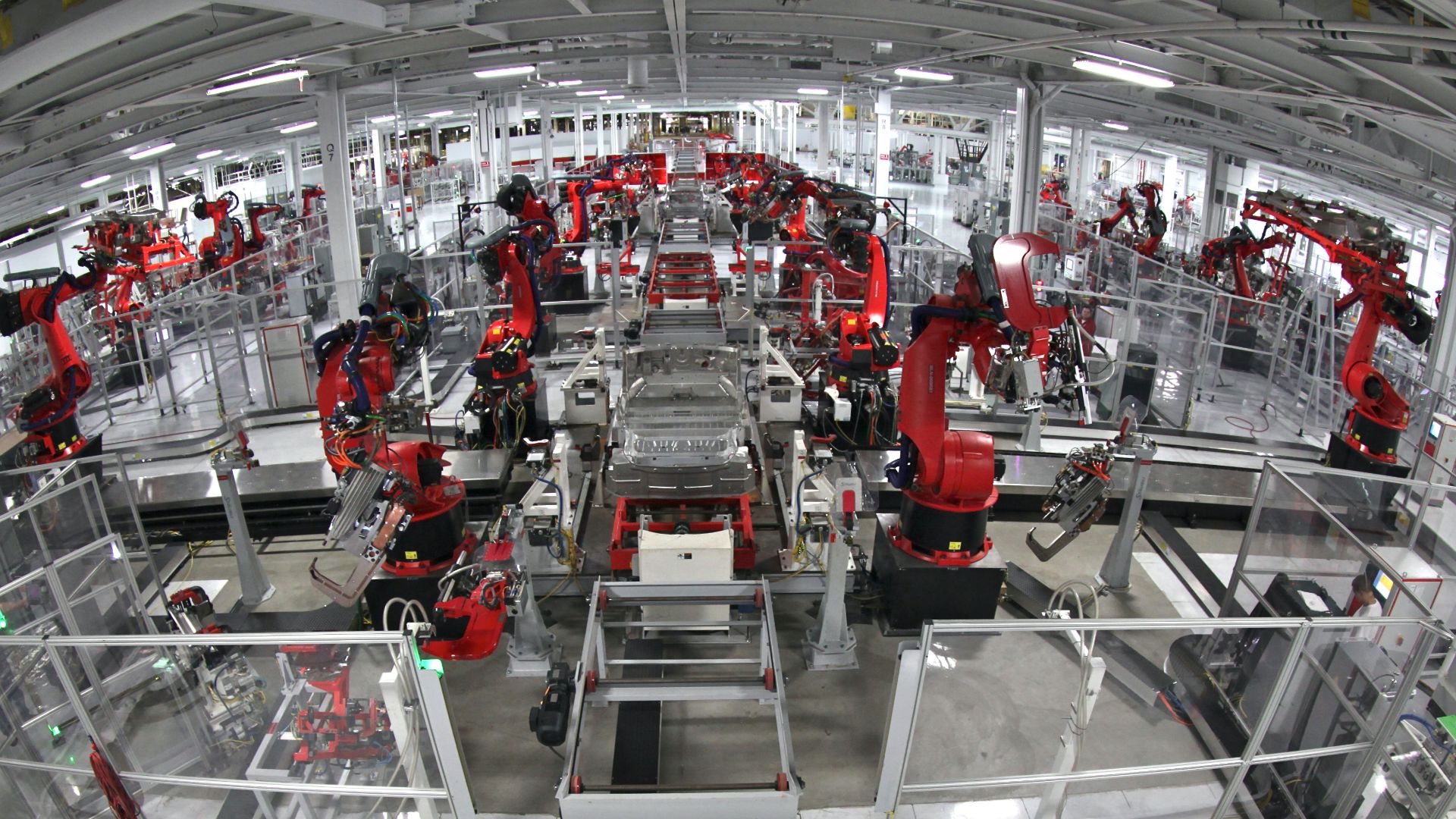

Share Architecture For Manufacturing Efficiency

Reusing proven stators, inverters, and cooling modules gave Tesla a production advantage. Standardized parts reduced costs and sped assembly lines while still delivering peak power. It’s smart engineering economics—enhanced performance without reinventing every bolt or circuit when refinement achieved the same gains.

Maurizio Pesce from Milan, Italia, Wikimedia Commons

Maurizio Pesce from Milan, Italia, Wikimedia Commons

Represent Elon Musk’s “No Limits” Design Philosophy

All details in the Plaid’s design carry the same stubborn optimism that defines Tesla’s culture. Instead of settling for incremental progress, engineers pushed to make impossible speeds normal. Such an attitude turns corporate ambition into tangible horsepower, echoing Elon Musk’s belief that limits exist only until tested.

Duncan.Hull, Wikimedia Commons

Duncan.Hull, Wikimedia Commons

Advance Software-Driven Torque Control

Tesla’s motor control software manages torque faster than human reflexes. Sensors feed microdata to algorithms that instantly balance traction on each wheel. Instead of mechanical differentials, code determines grip and stability. The result feels intuitive: smooth power delivery that reacts before the driver consciously adjusts.

Steve Jurvetson from Los Altos, USA, Wikimedia Commons

Steve Jurvetson from Los Altos, USA, Wikimedia Commons

Prevent Rotor-Burst At Extreme Speeds

Centrifugal forces at top RPM could destroy weaker materials. And that’s why Tesla engineered the rotor’s carbon wrap to withstand the immense outward pressure exerted on the copper core. That containment keeps the structure intact, and it enables incredible speed without structural failure.

Lower Maintenance Through Minimal Moving Parts

Complex gear systems create friction and wear, which, in turn, increase servicing costs. The Plaid motor sidestepped that by simplifying the drivetrain. Fewer mechanical joints mean fewer breakdowns. Owners get sustained performance with minimal upkeep.

Oleg Alexandrov, Wikimedia Commons

Oleg Alexandrov, Wikimedia Commons

Enable Precise Control Via Firmware Updates

Motor control evolves like software now. Tesla’s engineers tweak performance through over-the-air updates, fine-tuning torque maps and thermal limits without opening a hood. That adaptability turns every Plaid into a constantly improving machine, reflecting a future where performance grows through code rather than hardware.

Outperform Porsche Taycan Turbo S Rival

When Tesla benchmarked the Taycan Turbo S, it saw both competition and opportunity. The goal was dominance. Acceleration metrics and sustained output gave Tesla bragging rights, but the more resounding win lay in redefining electric luxury as faster, cleaner, and engineered for endurance.

Rutger van der Maar from Leiden, The Netherlands, Wikimedia Commons

Rutger van der Maar from Leiden, The Netherlands, Wikimedia Commons

Cement Tesla’s Halo-Innovation Leadership

Plaid technology serves as Tesla’s statement piece—proof of what’s possible before those breakthroughs ripple through the rest of its lineup. By turning extreme performance into something attainable, the company cemented its place as the EV industry’s innovation leader, where power itself becomes the message.

Reflect “Effortless Speed” Brand Ethos

Every aspect of the Plaid experience was tuned for calm confidence. Acceleration feels instant but controlled, creating motion that feels lighter than it should. Tesla’s engineers built performance to feel natural as a modern interpretation of luxury defined by silence, balance, and smooth intensity.

Steve Jurvetson, Wikimedia Commons

Steve Jurvetson, Wikimedia Commons

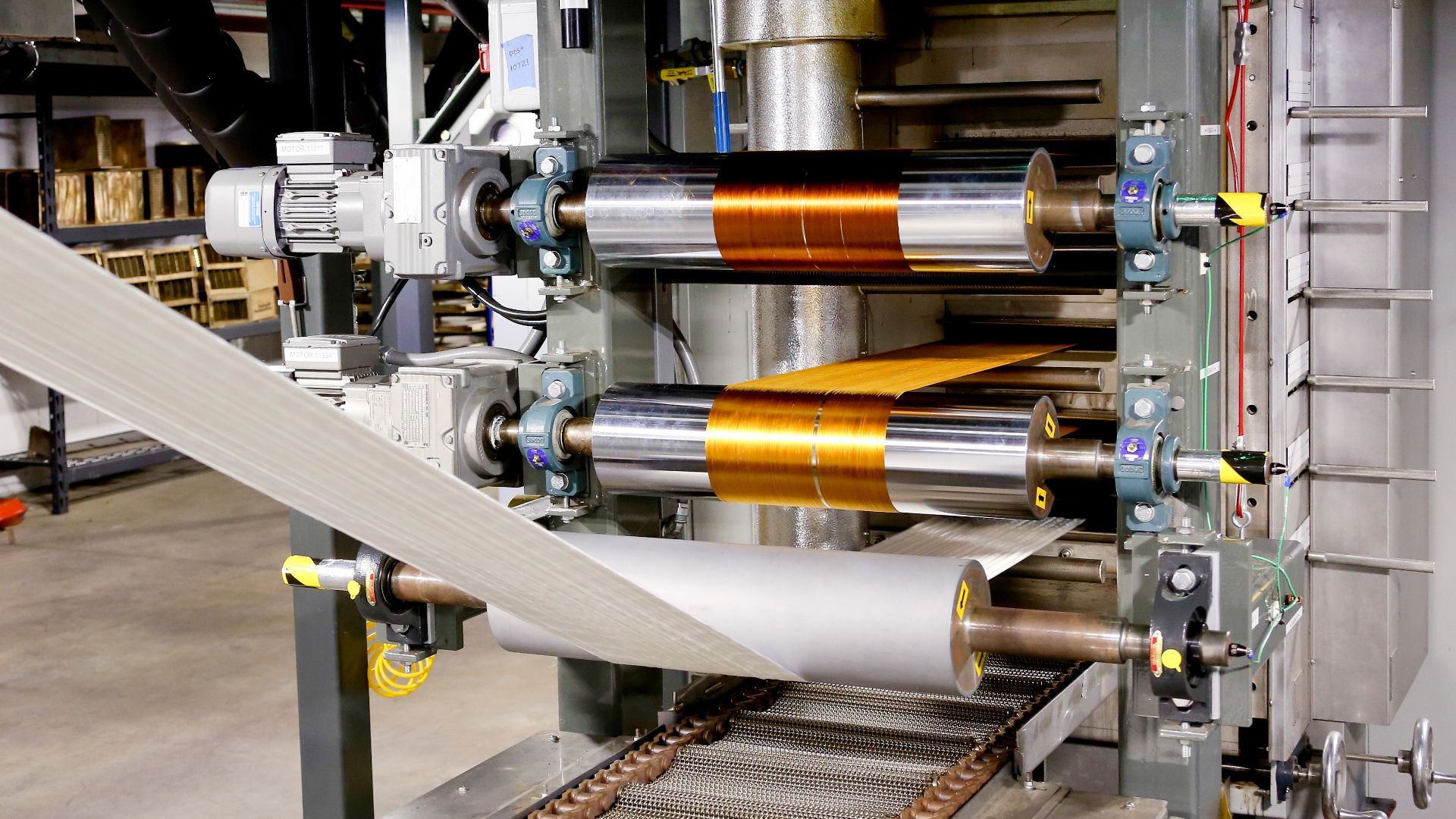

Integrate Oil-Cooled Stator For Efficiency

Instead of relying solely on air, engineers routed oil directly around the stator windings. This design removes heat faster and keeps power steady during extended runs. Sustained cooling ensures maximum efficiency since it turns what’s usually a thermal weakness into one of the motor’s strongest assets.

Strengthen Tesla’s Vertical Integration Strategy

In the long run, Tesla wanted control over the creation process. By producing motors, inverters, and even rotor materials internally, the company reduced dependency on suppliers. This approach allowed faster iteration, greater cost control, and seamless integration between mechanical components and proprietary software intelligence.

Maurizio Pesce from Milan, Italia, Wikimedia Commons

Maurizio Pesce from Milan, Italia, Wikimedia Commons

Guarantee Reliability Under Extreme Acceleration

High-speed launches strain tires and test engineering trust. The brand validated the Plaid motor under brutal cycles of acceleration and sustained heat, ensuring no performance fade. That durability cemented confidence that electric performance could last as long as the thrill itself.

Redefine Luxury Performance Sedan Standards

Luxury once meant leather and silence. Tesla redefined it as seamless acceleration, intuitive control, and minimal mechanical intrusion. This Plaid motor made that philosophy tangible, turning electric power into elegance. Driving became less about status symbols and more about sophisticated engineering done right.

Alexander-93, Wikimedia Commons

Alexander-93, Wikimedia Commons

Fuse Hardware And Software Excellence

Performance in Plaid is digital. Hardware provides raw capability, while software fine-tunes every electrical impulse. The partnership between silicon and steel creates precision beyond the reach of pure mechanics alone to showcase how Tesla’s software DNA has transformed traditional carmaking into an evolving performance platform.